Aircraft Fasteners » Screw threads

Screw Threads

Threaded fasteners allow parts to be fastened together with all of the strength that unthreaded fasteners provide. However, unlike rivets and pins, threaded fasteners may be disassembled and reassembled an almost infinite number of times. Due to the large range of different available fasteners, great care must be always be taken to select the correct fastener for each particular installation.

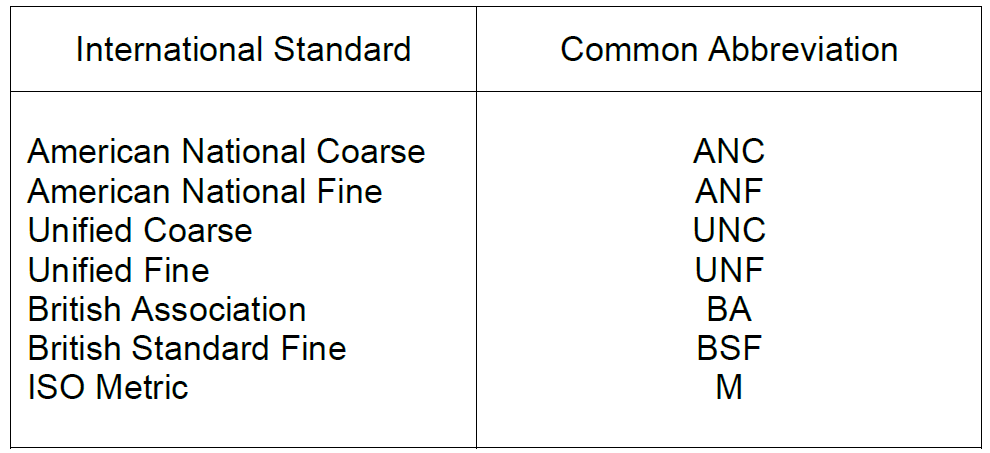

Aircraft, bolts, nuts, screws and studs are manufactured to the many different International Standards and in a variety of different thread forms, as can be seen in the following table.

Most aircraft now use unified or metric threads. However, some older aircraft use obsolete British Association (BA), British Standard Fine (BSF) or Whitworth (BSW) thread forms. None of these are compatible with the unified (or metric) thread forms.

The Inclined Plane and the Helix

The value of the wedge, as a means of transmitting motion, is well known. For a constant effort applied in driving a wedge, a smaller angle of inclination between the planes will cause a greater force to be exerted through a shorter distance. Conversely, a larger angle will cause less force to be exerted through a greater distance (refer to figure below).

FIGURE

Generally, whilst the wedge is used as a means of transmitting motion, it must be remembered that the action may be reversed and the wedge can be caused to move when a force is applied to the inclined surfaces.

This is readily appreciated when the angle is large (and the larger the angle of inclination becomes, the more readily is the motion reversed), but no matter how small the angle may be, the resultant of forces applied will still tend to produce movement. However, friction between the surfaces may prevent movement from actually occurring.

When a continuous, inclined plane is cut around the outside (or the inside) of a cylinder, then a spiral (also known as a ‘helix’) is produced (refer to figure below). The helix angle is important in screw threads, because it dictates the number of threads, which can be cut per axial linear increment (millimetres or inches) on/in the cylinder.

FIGURE

In a similar manner to the previously mentioned wedges, a thread with a small helix angle (a fine thread), will exert a greater force than one with a larger helix angle (a coarse thread) for a given cylinder diameter.

Normally, fine threads are associated with small and delicate instruments or in equipment, where secure holding power is often required of miniature-sized fasteners. The greater ‘wedging action’ of fine threads also makes them much more dependable in situations where vibration (or a change of temperature) has the tendency to loosen threaded joints.

Most aircraft components are assembled using fine threads on the various bolts, nuts, screws and studs, which are then further secured by some other mechanical process, to reinforce their resistance to the effects of temperature changes and vibration.